Our products

Liquids and gases flow through every industrial process and into every modern home. The hardware devices used to control flow have remained fundamentally unchanged for decades, and in some cases, centuries. Actuation Lab is developing its first two products to rid the world’s pipework of these energy sapping, high maintenance, outdated devices.

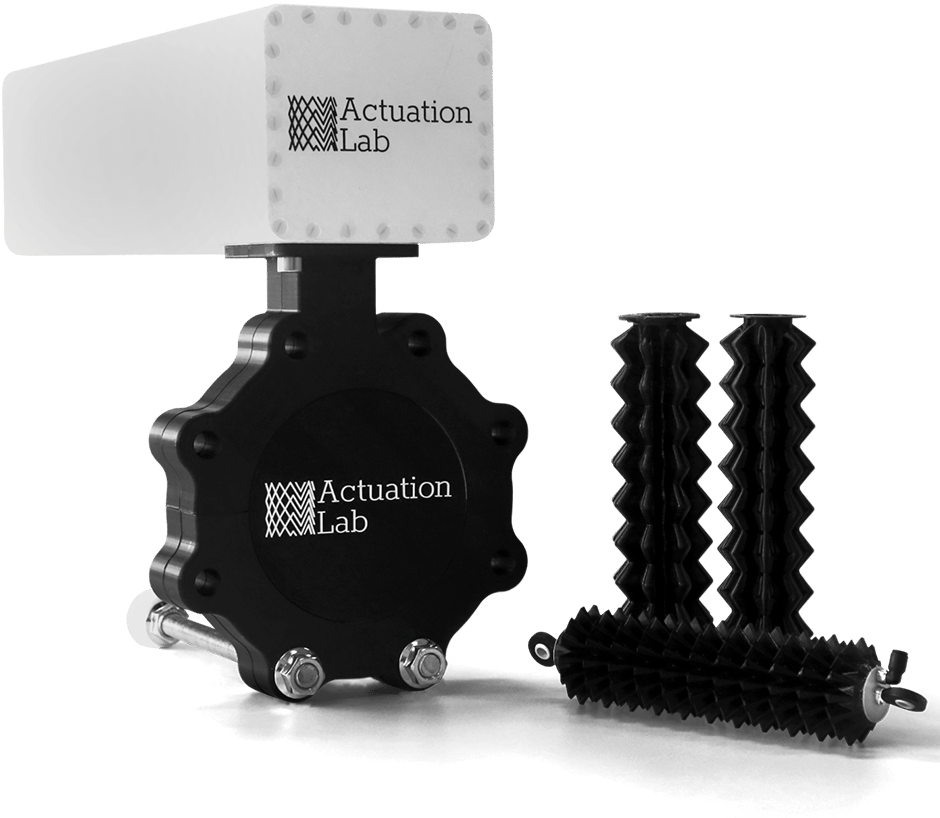

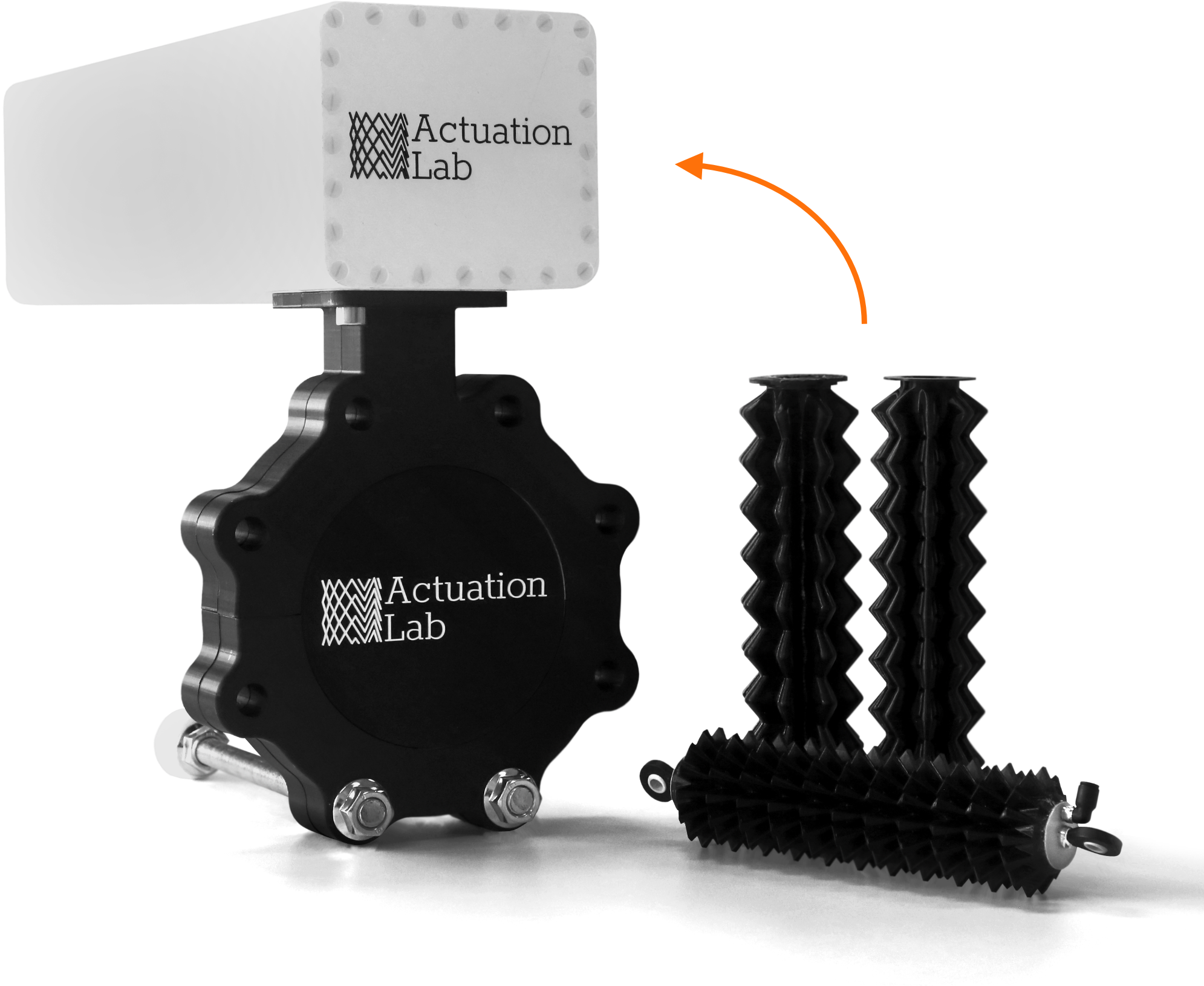

Callimorph^Actuator

Actuation Lab’s Callimorph Actuator takes the nuts and bolts and springs and shafts of the traditional actuator and replaces them with just a single moving part which is built from corrosion-free composite materials. We are first applying the Callimorph Actuator to operate valves in extreme conditions, working towards relieving the £368 million maintenance backlog of corroded and worn valve actuators in the UK energy industry, and reducing maintenance burdens worldwide.

Dragonfly^Valve

The use of hydrogen has the potential to eliminate over half the UK’s carbon emissions. However, hydrogen is the smallest element and can escape through microscopic openings and worn seals. Without innovation in UK gas infrastructure, 75,000 tonnes of hydrogen could be lost annually. This is £200 million of lost product and equivalent to 372,000 tonnes of CO2. This is where the Dragonfly Valve comes in.

Latest News

- 26.03.24

It was great to welcome the DESNZ team once again in our new premises in Bristol. This time we were able to share our newly added HURCO CNC machines. This [...]

- 13.02.24

Last month we were delighted to welcome our newest engineer, Alex Benton to the Actuation Lab team. He is taking on a role of Research and Development Engineer, having recently completed his Masters in [...]

- 31.01.24

Actuation Lab attended this year’s absolutely vibrant and buzzing Hyvolution Paris 2024, showcasing the cutting-edge present and future of hydrogen in the region. We were part of the UK delegation [...]